GRAPHENE: Mining and production Process

Graphene is typically produced through a process involving the extraction of graphite, which is a naturally occurring form of carbon. The mining and production of graphene involves several key steps:

-

Graphite Mining: Graphite is primarily mined from natural deposits. These deposits can be found in various locations around the world, including China, India, Brazil, Canada, and parts of Africa. The mining process involves extracting graphite ore from the earth’s crust.

-

Milling and Purification: The mined graphite ore undergoes milling and grinding processes to break down large chunks into smaller, more manageable pieces. The goal is to liberate the graphite flakes from the surrounding rock.

-

Flotation: After milling, the graphite ore is often subjected to a flotation process. In this step, chemicals are used to separate graphite particles from other minerals. The mixture is agitated, and air bubbles are introduced, causing the graphite to float to the surface for collection.

-

Concentration and Drying: The floated graphite is then concentrated further to increase its purity. This may involve additional separation steps or chemical treatments. Once the desired level of purity is achieved, the graphite concentrate is dried to remove excess moisture.

-

Synthesis of Graphene from Graphite: There are several methods for synthesizing graphene from graphite. One common approach is the chemical exfoliation method, where graphite is chemically treated to separate individual graphene layers. This can involve processes like chemical oxidation and reduction.

-

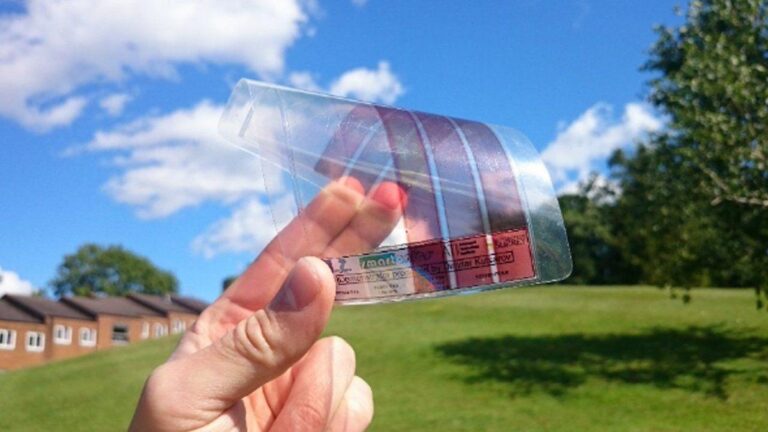

Mechanical Exfoliation (Scotch Tape Method): This is a simple but highly effective method for producing single-layer graphene. A piece of graphite is repeatedly cleaved using adhesive tape, leading to the creation of progressively thinner layers until single-layer graphene is obtained.

-

Chemical Vapor Deposition (CVD): This is a widely used method for producing large-area graphene sheets. It involves introducing a carbon-containing precursor gas, such as methane, into a high-temperature furnace along with a catalyst. Carbon atoms from the precursor gas deposit onto the substrate, forming a graphene layer.

-

Liquid Phase Exfoliation: In this method, graphite is dispersed in a solvent, and various techniques are employed to exfoliate the layers into graphene flakes. The resulting graphene dispersion can be used for various applications.

-

Characterization and Quality Control: Throughout the production process, various analytical techniques are used to characterize the graphene material, including electron microscopy, atomic force microscopy, and Raman spectroscopy. These tools help ensure that the graphene meets specific quality and purity standards.

It’s important to note that the production of high-quality graphene is a complex and often resource-intensive process. Additionally, there are ongoing research efforts to develop more efficient and scalable methods for graphene production, as well as to explore alternative sources of graphene-like materials. These advancements aim to make graphene more accessible for a wider range of applications across industries.